Why Tile Grout Cracks in Floor Joints: Movement, Joint Width, and Installation Errors

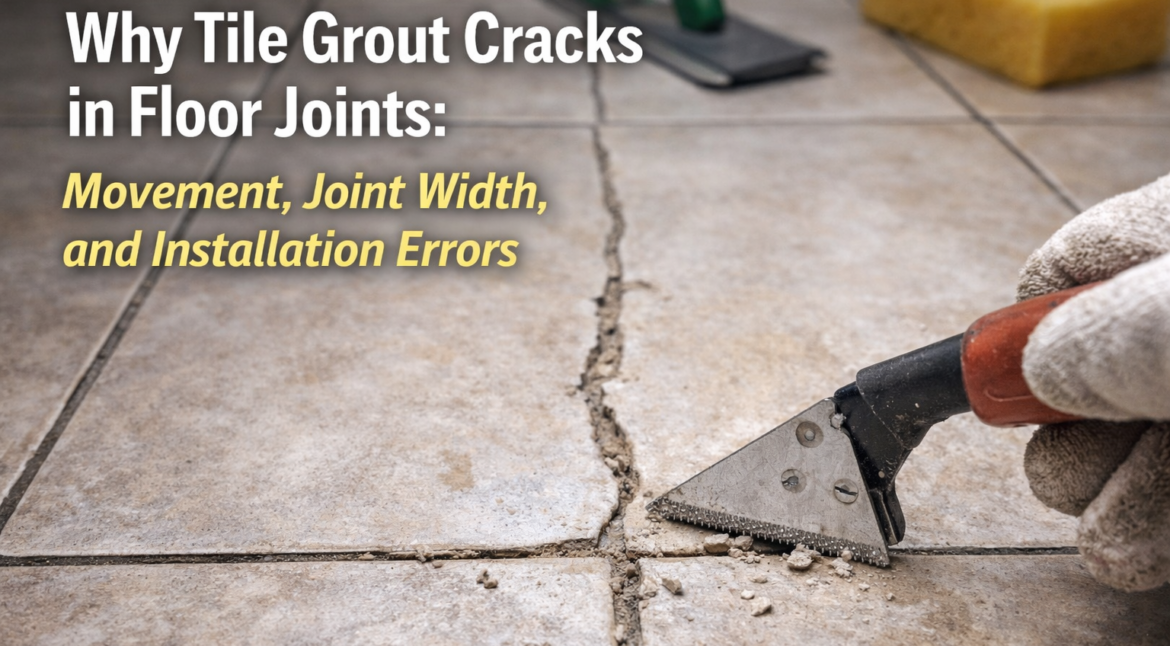

Cracked grout lines are one of the most common complaints in floor tiling projects. A newly finished surface may look perfect on day one, but after a few weeks or months, grout joints begin to show hairline cracks, gaps, or even powdering at the edges.

Many people assume the grout product was poor. In reality, grout cracking is rarely caused by the material alone. Most failures occur because floor joints move, joint widths are not respected, or installation practices weaken the grout line before it ever cures properly.

Understanding why tile grout cracks in floor joints requires looking at the full system, the substrate, tile layout, joint design, and the type of grout selected.

Common Question Asked

Q.1 Can tile grout crack even when the tiles are installed correctly?

Yes, tile grout can crack due to floor movement, incorrect joint width, poor curing, or choosing the wrong grout type for the application.

Why Floor Tile Grout Cracking Is So Common

Floor joints behave differently from wall joints. Floors are constantly exposed to:

- Foot traffic and impact loads

- Thermal expansion and contraction

- Substrate deflection

- Moisture movement in wet zones

Unlike tiles, grout is not a rigid structural element. It is a joint filler that must accommodate small movements without breaking. When movement exceeds grout tolerance, cracks appear.

This is why selecting the right tile grout system and applying it correctly is critical for long-term floor performance.

Redwop offers a full range of tile grout solutions for both cement-based and epoxy-based joint requirements.

Cause 1: Substrate Movement and Floor Deflection

One of the biggest reasons for grout cracks is movement below the tile surface.

Common sources of movement include:

- Shrinkage in new concrete slabs

- Settlement in screeds

- Vibration in commercial floors

- Expansion due to temperature changes

Even slight flexing causes stress concentration at grout joints. Cementitious grout, in particular, has limited flexibility and will crack if movement is ongoing.

In movement-prone floors, grout selection must match structural behavior.

Cause 2: Incorrect Joint Width Design

Joint width is not just an aesthetic choice. It directly affects grout durability.

Too Narrow Joints

Very tight joints:

- Restrict grout depth

- Reduce the bonding area

- Increase the cracking risk

Too Wide Joints

Excessively wide joints:

- Require high-strength grout

- Increase shrinkage potential

- Need polymer modification or epoxy systems

Correct joint width depends on tile size, substrate movement, and application zone.

This is why professional tiling systems specify different grout types for different joint widths.

Cause 3: Using the Wrong Type of Tile Grout

Not all grout types perform the same.

Cement Tile Grout Applications

Cement tile grout is widely used for residential and general floor tiling. It provides:

- Easy application

- Cost-effective joint filling

- Suitable performance in normal dry zones

Redwop’s cement-based grout solutions are designed for consistent strength and smooth finishing in standard floor joints.

A product example used for routine floor grouting is Redwop’s Tile Grout formulation.

However, cement grout is more prone to cracking when:

- Floor movement is high

- Joint width is inconsistent

- Wet chemical exposure exists

Epoxy Tile Grout for High-Performance Floors

For demanding environments, epoxy tile grout provides superior resistance and durability.

Epoxy grout is ideal for:

- Commercial kitchens

- Swimming pools

- Industrial floors

- High-moisture wet zones

Unlike cement grout, epoxy systems offer:

- Higher bond strength

- Better crack resistance

- Chemical and stain resistance

Redwop offers specialized epoxy grout systems here:

A commonly specified product is EPTile Grout, used in heavy-duty flooring applications.

For decorative or premium flooring, variants such as EPTile Grout Sparkle are also available.

Epoxy grout is often the better choice when floor joints face movement and harsh cleaning cycles.

Cause 4: Poor Mixing and Excess Water Addition

Cement grout cracking is frequently caused by incorrect mixing.

Common errors:

- Adding extra water to improve spreadability

- Re-tempering grout after initial set

- Mixing inconsistent batches across joints

Excess water leads to:

- Higher shrinkage

- Reduced strength

- Powdering joints

Grout should always be mixed according to the manufacturer’s ratios to maintain performance.

Cause 5: Improper Joint Filling Depth

Shallow grout joints crack faster because they lack structural depth.

Common site mistakes include:

- Not cleaning the adhesive from the joint gaps

- Partial filling of joints

- Poor compaction during application

A grout joint must be fully packed to ensure proper load distribution under traffic.

Cause 6: Lack of Expansion and Movement Joints

Large tiled floors require movement joints to absorb thermal expansion.

Without expansion joints:

- Stress transfers directly into grout lines

- Random cracking appears across the floor

- Tiles may debond over time

Grout cannot replace expansion joints. Both must work together.

How to Prevent Tile Grout Cracking in Floor Joints

A reliable prevention strategy includes:

- Ensuring stable substrate before tiling

- Selecting correct grout type (cement vs epoxy)

- Maintaining proper joint width

- Mixing grout without excess water

- Packing joints fully to correct depth

- Providing movement joints in large areas

- Curing grout properly before heavy traffic

When grout selection and installation practices align, floor joints remain durable for years.

Conclusion

Cracking in floor grout joints is rarely a simple product issue. It is usually caused by substrate movement, incorrect joint width, improper mixing, or selecting the wrong grout system for the application.

Standard cement tile grout works well in stable residential floors, but high-stress or wet environments often require epoxy tile grout for long-term durability.

By understanding movement behavior, respecting joint design, and choosing the right tile grout system, contractors can prevent cracking, reduce maintenance, and deliver floors that remain structurally and visually intact over time.

FAQs

-

1. Why does tile grout crack in floor joints?

Floor movement, incorrect joint width, and poor installation practices are the most common causes.

-

2. Is cement tile grout suitable for all floors?

No. Cement grout works in stable dry zones but may crack in high-movement or wet areas.

-

3. When should epoxy tile grout be used?

Epoxy grout is best for commercial kitchens, pools, industrial floors, and chemical exposure zones.

-

4. Does adding extra water cause grout cracking?

Yes. Excess water increases shrinkage and reduces grout strength.

-

5. Can grout cracking be prevented completely?

Yes, with proper substrate preparation, correct grout selection, and movement joint planning.