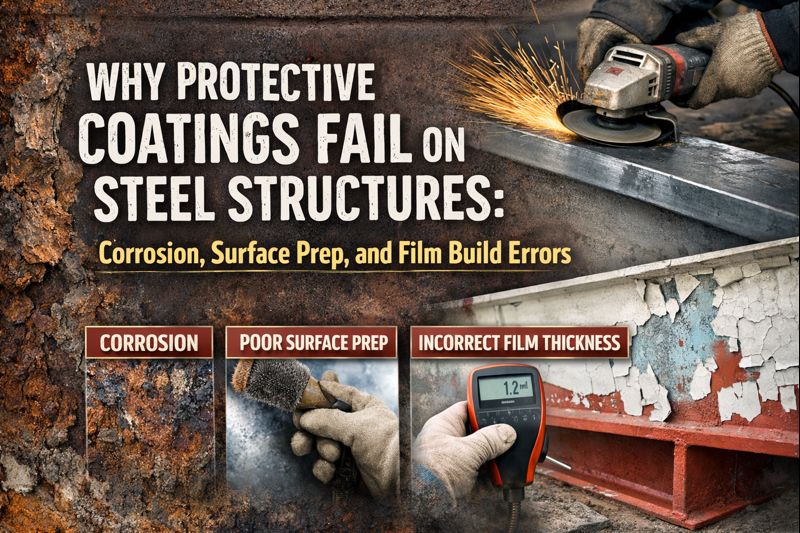

Why Protective Coatings Fail on Steel Structures: Corrosion, Surface Prep, and Film Build Errors

Steel structures are designed to serve for decades. Yet in real projects, we often see rust bleeding through paint, coating flakes falling off beams, corroded handrails, and industrial frames requiring repainting far earlier than expected.

In most cases, the steel itself isn’t the problem. And surprisingly, the coating product alone isn’t either. Failures usually happen when protective coatings are selected without considering exposure conditions, or when surface preparation and film thickness control are rushed on-site.

Understanding why protective coatings fail on steel structures comes down to three core factors: corrosion behavior, surface preparation, and coating film build. When any one of these is compromised, even high-performance coating systems underdeliver.

Common Question Asked:

Q.1 Can protective coatings fail even when premium products are used?

Yes, poor surface preparation, incorrect system selection, or wrong film thickness can cause protective coatings to fail prematurely, regardless of product quality.

Why Steel Needs Protective Coatings

Steel corrodes when exposed to:

- Moisture and humidity

- Atmospheric oxygen

- Coastal salts

- Industrial fumes

- Chemical vapors

Once corrosion starts, it spreads beneath paint films, causing blistering, peeling, and section loss. This is why structural steel relies on protective coating systems to isolate metal from aggressive environments.

Redwop offers a complete protective coating range developed for steel protection in industrial, commercial, marine, and infrastructure projects.

Failure Cause 1: Wrong Coating System for the Corrosion Environment

Not all steel faces the same exposure risk. A warehouse roof truss, a coastal transmission tower, and a chemical plant pipeline require very different protection strategies.

A common mistake is applying general paint where engineered anticorrosive coatings are required.

For outdoor and industrial steel, Redwop’s anticorrosive coating systems are designed to control corrosion at the metal interface. Systems such as REDOPOXY’s range of epoxy paints provide durable barrier protection, while Zichrich offers zinc-rich coatings for high-corrosion environments. In damp interior or condensation-prone zones, Dampcoat helps control moisture-driven corrosion.

When corrosion category and exposure severity are not evaluated before selecting a coating, early rust breakthrough becomes inevitable.

Failure Cause 2: Poor Surface Preparation

Most protective coating failures begin before the coating is applied.

Common site shortcuts include:

- Painting over mill scale

- Leaving rust patches untreated

- Applying coating on oily or dusty steel

- Inadequate abrasive blasting or wire brushing

When coatings cannot properly anchor to steel, adhesion loss and peeling occur quickly.

Even high-performance epoxy coating systems require properly prepared surfaces. Redwop’s epoxy coating range, including ZINCRICH, REDOPOXY, REDOPOXY 320, REDOPOXY 630, REDOPOXY 630HB, is engineered for strong adhesion and chemical resistance, but only when applied over clean, profiled steel.

Skipping preparation is the single most expensive mistake in steel protection projects.

Failure Cause 3: Incorrect Film Thickness

Coating thickness defines how long steel remains protected.

Under-build

- Weak moisture barrier

- Faster oxygen penetration

- Early corrosion initiation

Over-build

- Cracking of the film

- Solvent entrapment

- Poor curing

- Adhesion loss

Every protective coating system is designed for a specific dry film thickness. Whether using anticorrosive primers or epoxy intermediate coats, film thickness must be measured and controlled on-site. When thickness is guessed rather than monitored, coating life becomes unpredictable.

Special Case: Underground and Water-Contact Steel Structures

Steel in buried or permanently damp environments faces:

- Soil moisture

- Groundwater salts

- Microbial activity

- Constant wet conditions

In these applications, standard anticorrosive or epoxy systems alone may not provide sufficient resistance. This is where coal tar epoxy coating systems are essential.

EPKote ET140 coal tar epoxy coating is developed for pipelines, underground steel, foundation members, and water-contact structures where continuous moisture exposure accelerates corrosion. Using ordinary coatings in these zones leads to hidden corrosion and costly structural repairs.

Failure Cause 4: Incorrect Coating System Sequencing

Protective coatings are designed as multi-layer systems, not single coats.

Common sequencing errors:

- Skipping anticorrosive primer

- Applying epoxy topcoat directly on bare steel

- Mixing incompatible coating chemistries

This results in:

- Intercoat adhesion failure

- Premature peeling

- Reduced service life

Anticorrosive primers, epoxy build coats, and finishing layers each perform a specific role. Breaking the system breaks the protection.

Failure Cause 5: Poor Application Conditions

Protective coating application is sensitive to:

- High humidity

- Condensation on steel

- Low surface temperature

- Wind-borne dust

Applying coatings under unsuitable conditions traps moisture, causes pinholes, and prevents proper curing, especially with epoxy coating systems that rely on controlled chemical reactions for full performance.

How to Prevent Protective Coating Failures on Steel

Successful steel protection requires:

- Correct corrosion exposure assessment

- Selection of suitable anticorrosive, epoxy, or coal tar epoxy systems

- Proper surface preparation to specified cleanliness standards

- Controlled film thickness measurement

- Correct coating sequence

- Application under suitable environmental conditions

Protective coating performance is achieved through process discipline, not guesswork.

Conclusion

Protective coatings on steel structures fail not because coatings are weak, but because corrosion risks are underestimated, surface preparation is rushed, and film thickness is poorly controlled. Even premium anticorrosive coatings, high-performance epoxy coating systems, and heavy-duty coal tar epoxy coatings cannot perform if basic coating principles are ignored.

When coating systems are selected based on exposure conditions, applied over properly prepared steel, and built to correct thickness, protective coatings deliver long-term corrosion protection and extend the life of steel structures significantly. For more information, Contact Us.

FAQs

-

1. Why do protective coatings peel off steel?

Poor surface preparation and contamination are the most common causes.

-

2. Are anticorrosive coatings necessary for indoor steel?

Yes. Condensation and industrial fumes can still trigger corrosion indoors.

-

3. Can epoxy coating be applied on rusted steel?

No. Rust must be removed to the required preparation standard first.

-

4. Where is coal tar epoxy coating typically used?

In underground steel, pipelines, and water-contact structures.

-

5. What is the most common steel coating mistake?

Skipping proper surface preparation and film thickness control.