Non Shrink Grout

We offer high-quality non-shrink grout solutions designed to provide durable and stable bonding for construction projects. Our epoxy grout and epoxy-based grout products ensure excellent performance for filling gaps and joints, offering resistance to shrinkage and maintaining structural integrity. Whether it’s for flooring, tiling, or heavy machinery foundations, our epoxy grouting chemicals provide superior strength and reliability. We take pride in being a trusted epoxy grout supplier in India, catering to diverse construction needs.

Redwop Non‑Shrink Grout is a factory-prepared, high-strength, fiber-reinforced cementitious grout engineered to maintain volume during curing. Pre-mixed with shrinkage-compensating additives and alkali-resistant fibers, it cures to a dense, durable mass with compressive strength exceeding 70 MPa (10,000 psi). Ideal for precision structural projects, it guarantees firm bedding and accurate load transfer without settlement across various construction conditions.

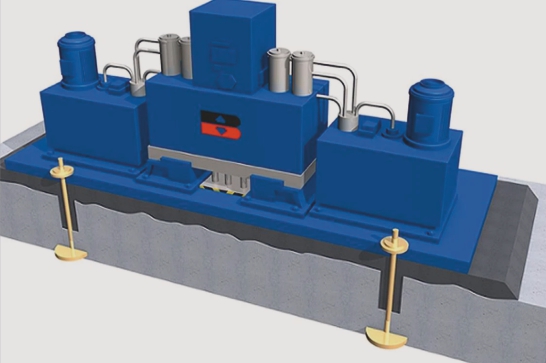

Ideal Applications

Engineered for heavy-duty structural uses, this grout is perfect for machinery base plates, anchor bolts, crane rails, railway track beds, precast column bases, bridge bearings, and elevator pits. It equally supports flooring transitions in concrete slabs and steel structures. Whether used in manufacturing plants, bridges, or residential installations, it guarantees superior load distribution and crack-free anchoring performance—even under seismic, thermal, or impact stresses.

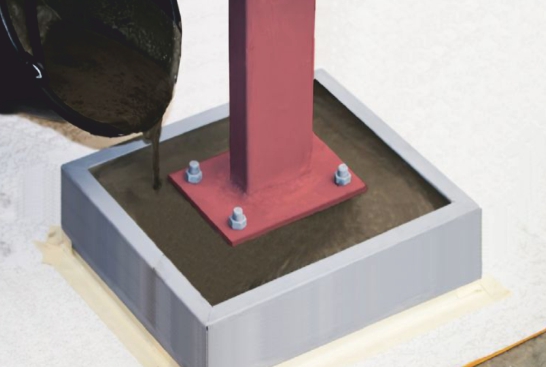

Application Guide

Mix approximately 2.4–2.6 L water per 25 kg bag until achieving a smooth, lump-free consistency. Adjust water volume for desired flow— less for dry-pack, more for pourable mixes. Apply the grout immediately after mixing; pour continuously, using tremie or pump methods for deep fills to prevent air entrapment. For dry-packing jobs (e.g., post bases), use a mortar bag or hand pack tightly. Maintain continuous grout flow at ends, taper edges with a margin trowel, and wet-cure for at least 24 hrs under protected conditions. Avoid freezing or extreme heat during stacking.

Key Features & Benefits

Redwop Non‑Shrink Grout offers volume stability—compensating for drying shrinkage to ensure intimate contact between critical components. Reinforced with high-performance fibers, it vastly improves crack resistance and structural integrity, especially under dynamic loads and vibrations. Its non-ferrous, non-corrosive formulation prevents rusting of embedded steel. With customizable workability—from pourable to dry-pack—it adapts to diverse applications, cutting labor time without sacrificing performance or precision.

FAQ's

Non-shrink grout is a high-strength material used to fill gaps and joints in construction, offering excellent resistance to shrinkage and long-term durability.

Non-shrink epoxy grout is made with epoxy resins, providing enhanced adhesion, strength, and resistance to chemicals compared to traditional cement-based grout.

Yes, epoxy grout is highly durable and resistant to moisture, making it ideal for both indoor and outdoor applications, including exposed surfaces.

Epoxy base grout offers superior bonding, resistance to chemicals, high compressive strength, and a long-lasting finish, making it perfect for heavy-duty applications.

Redwop Chemicals is a trusted brand for premium-quality epoxy grouting chemicals in India, ensuring consistent performance and reliable customer support.

Unlike normal cement, Redwop Non‑Shrink Grout includes additives that prevent volume loss during setting and reinforcement fibers to control cracking, offering stable support over time.

Yes—use 2.4 L water for pourable mix, or reduce water to create a stiff dry-pack suitable for hand application or mortar bags.

It typically achieves over 70 MPa (10,000 psi) after 28 days, per ASTM C109 standards.

Absolutely—a pourable consistency makes it suitable for pumping. For deep fills, ensure continuous placement and exclude air.

Yes—fiber reinforcement and a non-ferrous, non-corrosive mix ensures steel surfaces remain protected from rust.

It supports light loads in 24 hours, with full strength developed in 7 days and optimal properties at 28 days.

Yes—must use warm mixing water and protect from freezing for at least 48 hours during cure.

Yes—adjust consistency or use pumping/dry packing methods to accommodate irregular or deep joints up to 100 mm.

A 25 kg bag produces ~13 L of grout. Coverage depends on volume; use calculators for precise estimation.

Fibers enhance tensile strength, resist shrinkage cracking, improve durability, and prolong service life under dynamic loading conditions.